EVERTZ Scarfing Machine 009

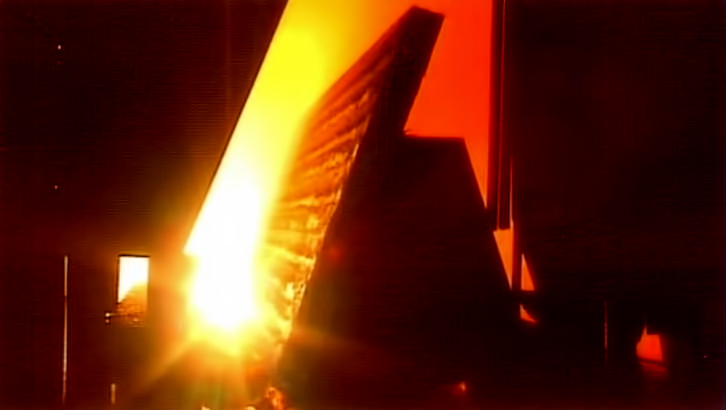

The most modern high-capacity scarfing machine of its kind in the world. The scarfing demonstrations have been completed successfully. The machine is operated manually.

Advantages: Best view of the torch and the slab; immediate recognition and removal of defects during the scarfing process.

The operator can react immediately.

Slabs of 90 t and above can be scarfed.

We are constantly upgrading and improving our gas technology. In the case of upgrades and improvements the retrofitting of machines with older gas systems is guaranteed. Current investigations: e.g. impulse scarfing.

For brown fume (FeO) reduction we offer our dedicated proprietary technology.

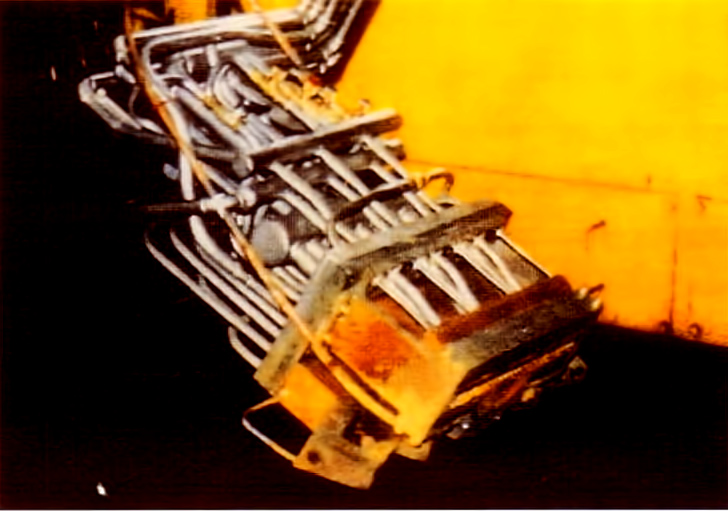

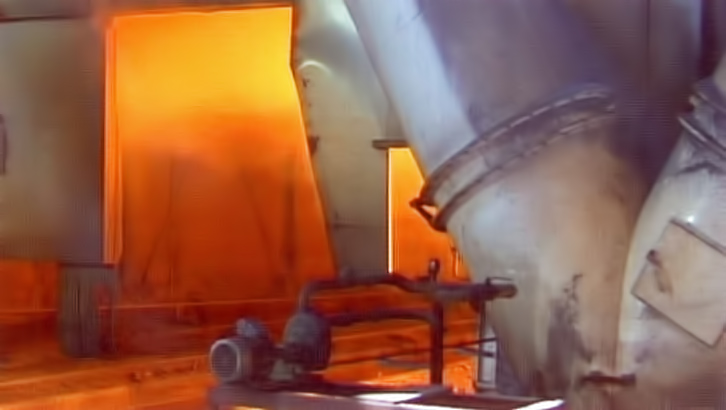

Type 009 Action

Type 009 Action

EVERTZ Hydro Descaling System

Scafed broad face of a slab

Scarfed edge area of slab

Technical Information

Scarfing of slabs

All-surface, narrow face and selective scarfing

at speeds between 8 and 25 m/min.

Scarfing widths from 100 mm to 450 mm.

Reduced oxygen consumption to 2400 Nm/h

Water-cooled torch with customized designs ensure long

service live.

Fast igniting through iron powder addition.

Torch manipulation guarantees max. capacity and

one time ignition.

Minimal ridge between the scarfing cuts. Scale free surfaces

thanks to a universal descaling system (proprietary process

of EVERTZ-Hydrotechnik).

Several selectable scarfing programmes with the same

torch — enabling among others the selection of the desired

scarfing depth.

Scarfing times

Scarfing one broad face of an approx. 45 t slab, having a length

of approx. 13 m, a width of 2000 mm and a thickness of

220 mm (= approx. 26㎡), takes approx. 6 minutes.

Capacities

Depending on the desired widths of the cut, capacities of more

than 100.000 t per month are possible.

EVERTZ Scarfing Car

The EVERTZ Scarfing machines were not sold one the market. Within the framework of complete scarfing service packages, the machines were operated by specially trained EVERTZ personnel. This service also included maintenance and repair and was paid on a price per square meter or tonne basis. EVERTZ guaranteed quality, performance and around-the-clock availability.

The custormer was relieved from the duty of keeping permanent stocks of spqre parts, as EVERTZ kept the necessary inventories of spare modules or even complete replacement machines.

Wherever costs play a role there was, and today there still is, no economic alternative to this EVERTZ approach.

E.Evertz himself wrapped the torch head with asbestos cloth in 1965

Test in the Langenfiled plant

A mobile oxygen plant and vaporizer provided sufficient and constant pressure

EVERTZ Scarfing Machine with Angled Torch

Subject: Automatic scarfing

Attached to this memo is a report by Dipl.-Ing. Stadler on scarfing tests performed on September 12, 1969. In this context I should like to refer to the confidential photocopies a test report of December 5, 1968.

...In any case we should pursue the develoment of a mechanized scarfing process using several burners with and without iron powder, like we developed about one-and-a-half years ago when we started our scaring activities in Langenfeld and performed tests with a bundle of oxygen bottles. The lack of the necessary oxygen supply pressure of 15 atu at that time induced me to install...

...iron powder feeding.

It's already more than 20 years ago!

MECHANICAL ENGINEERING

SURFACE TREATMENT

The mechanical engineering division of Egon Evertz KG has for many

years been dedicated to the solution of problems in connection with the

surface treatment of ferrous and non-ferrous metals products.

Due to our close relationship with the steel industry we have always obtai-

ned hands-on knowledge of the problems that are encountered by rolling

mill and steelplant operators.

Thanks to the development of a series of specialized scarfing, milling and

grinding machines it is now possible to process the above mentioned pro-

ducts economically, efficiently and at a high quality level.

These specialized surface conditioning tasks are performed at our own

facilities or, on request, at our many customers' sites domestic and

internationally.

Scarfing machine during bloom treatment

We would especially like to emphasize our expertise and capabilities in the surface treatment of high-quality, high-grade steel products.

Our technicians are available at any time to answer your questions and provide advice.

US Patent Granted

US Patent granted to Egon Evertz in 1973/1983

1973

US Patent granted to Egon Evertz in Scarfing Car

1983

CO2 injection for the reduction of fume generation

Not to be forgotten...

...that, besides EVERTZ in Germany, many years ago in France Dipl. -ing. Donze also pioneered the scarfing technology.He was a renowned and excellent specialist in the field of gas techenology - which is evidenced by the design of his gas nozzles.

Scarfing machine during bloom treatment

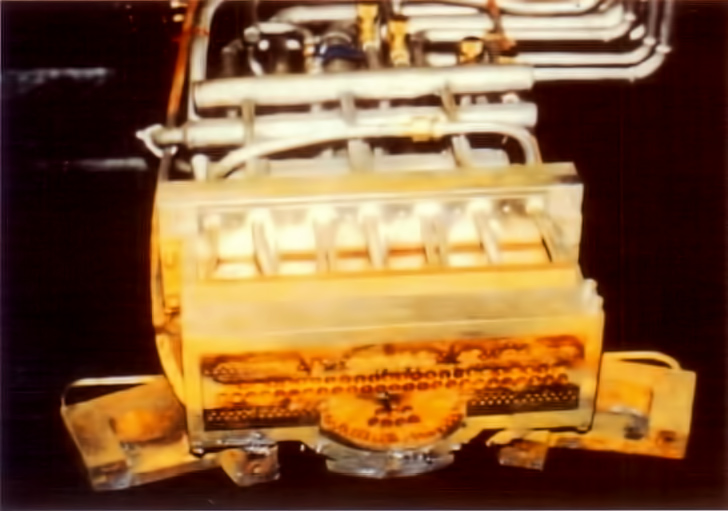

Systematic Layout of

the EVERTZ Scarfing Machine

Stationary Scarfing Machine Type 007

during Practical Operation

Set-up of the machine

Machine during operation

Part of th dedusting plant

Machine during operation

Feeding area of the scrafing machine

Loading of the scarfing car

Slab scrafed without hydro descaling system

Adhering slag can be removed by a small spatula