EVERTZ New Logo

Field of application:

Hot-and Cold Rolling Mills for Steel, Aluminium, Copper, as well as Forging Presses, Tube test installations, Mining, Paper industry, Off Shore, etc.

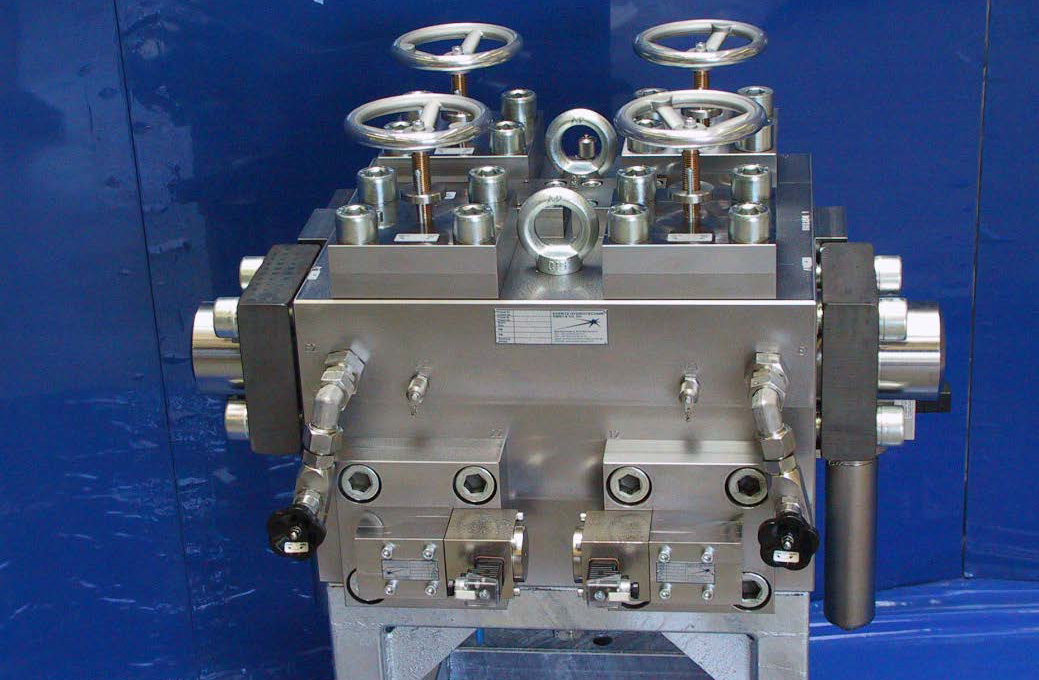

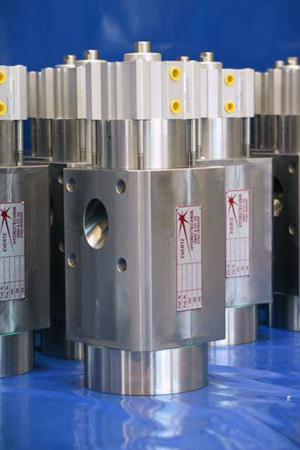

Valve Technology for Descaling Plants

Descaling Valve Unit DN80/DN63 PN475–4-fold / 6-fold

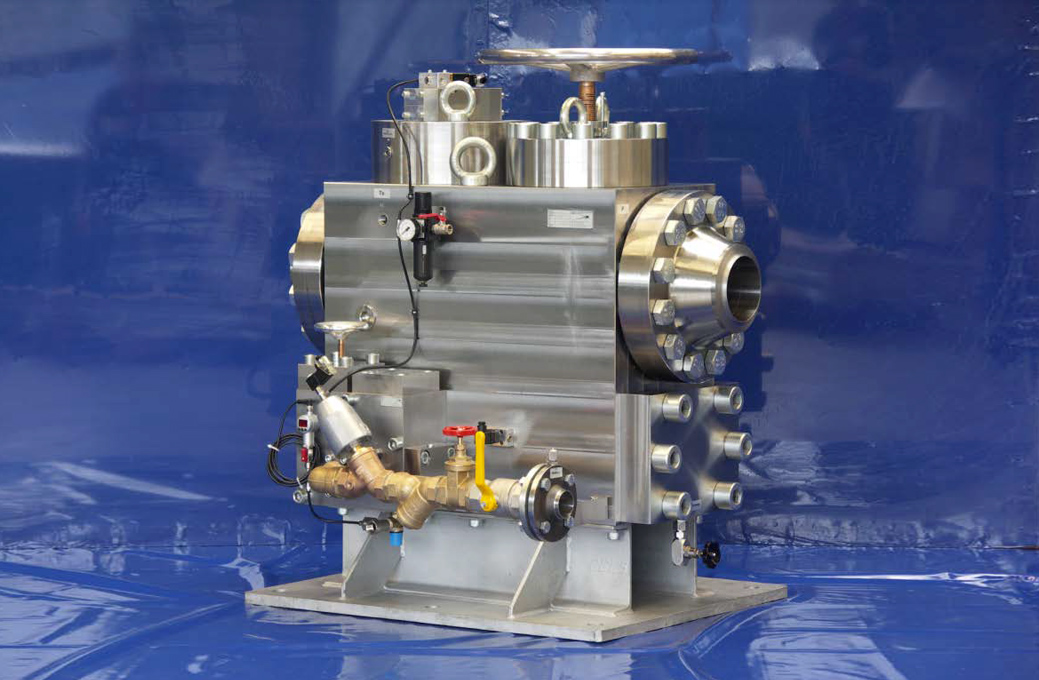

HP²compact -Valve Technology for Descaling Plants

Descaling Valve Unit DN80 & DN150 PN250

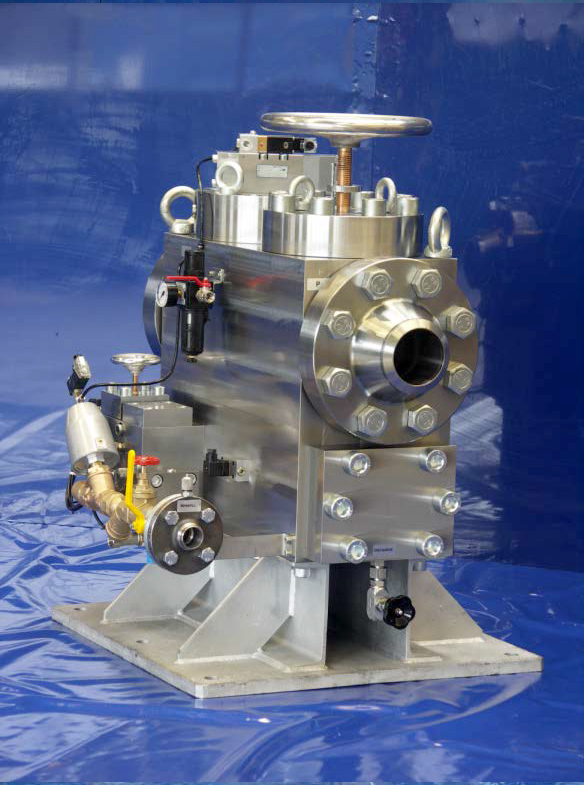

HP²compact -Valve Technology for Descaling Plants

Valve Combination DN63 PN250; redundant descaling system

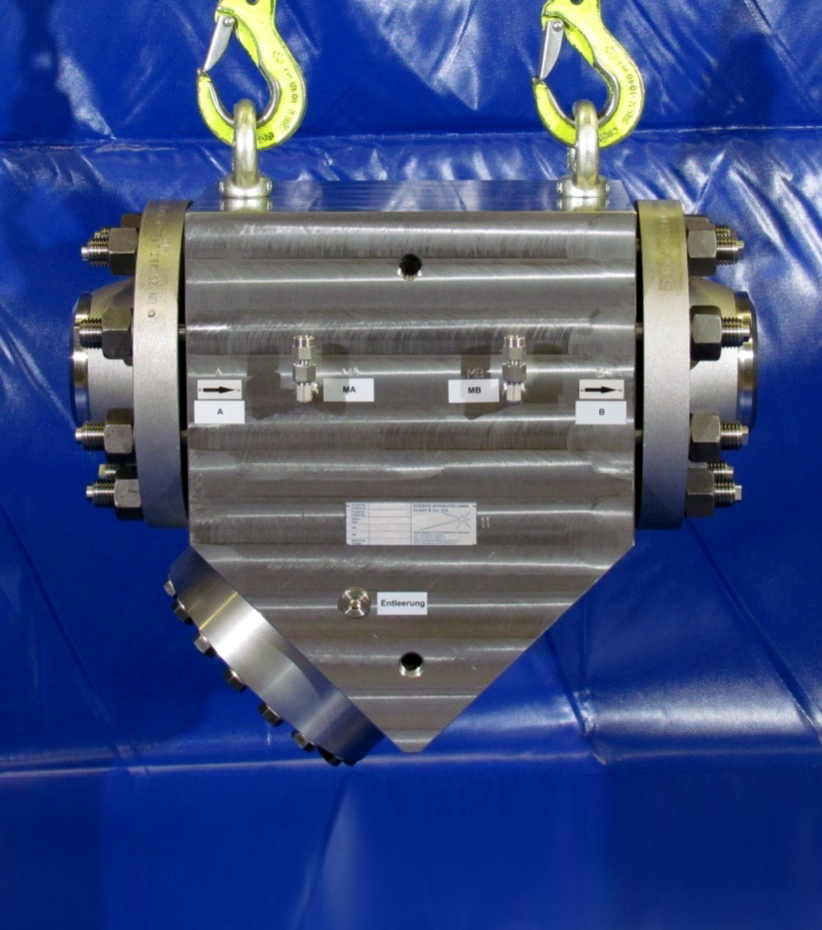

HP²compact - Valve Technology for Descaling Plants

Valve Units DN150 & DN100 PN320 for descaling

HP²compact - Valve Technology for Descaling Plants

Valves for a complete Descaling Plant

HP²compact -Valve Technology for Descaling Plants

- High Pressure Application - operating pressure 400bar

- for high flow speed up to 7m/sec

- compact design

- Valve protection / nozzle protection

Y-Strainer (High Pressure)

Last Chance Filter

Complete Descaling Plants

Descaling Box

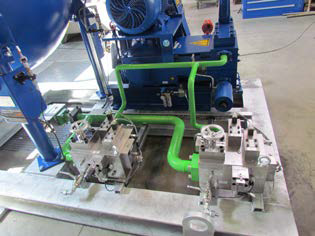

Complete Descaling Plants

Pump Station; Filter Station; compl. Valve Technology

Complete Descaling Plants

High Pressure Accumulator Units

High Pressure Accumulator Unit 3000l PN250 compl.

High Pressure Accumulator incl. level measuring, Accumulator Shut-off Valve, Compressor Unit

High Pressure Accumulator Unit 1500l PN100 compl.

High Pressure Accumulator incl. level measuring, Accumulator Shut-off Valve, Compressor Unit, Control Cabinet

High Pressure Accumulator Unit 2000l PN100 compl.

High Pressure Accumulator incl. level measuring, Accumulator Shut-off Valve, Compressor Unit, Control Cabinet

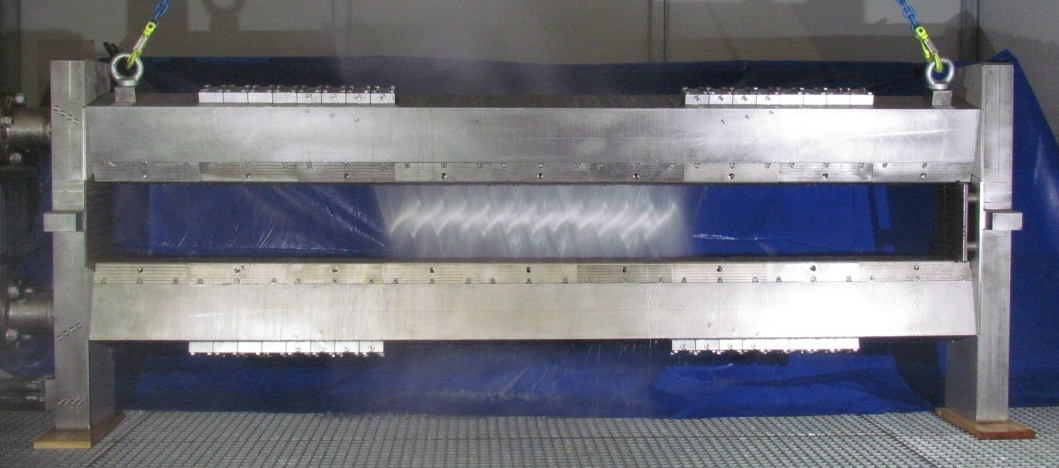

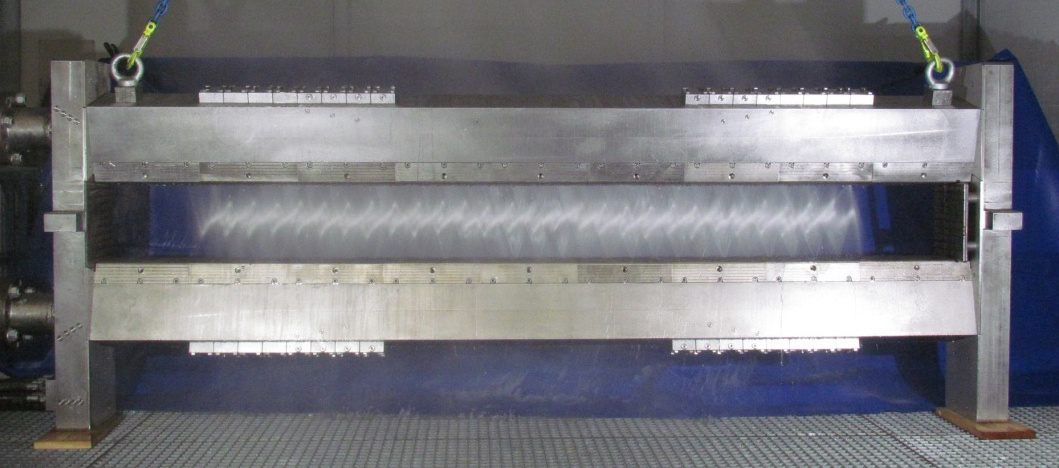

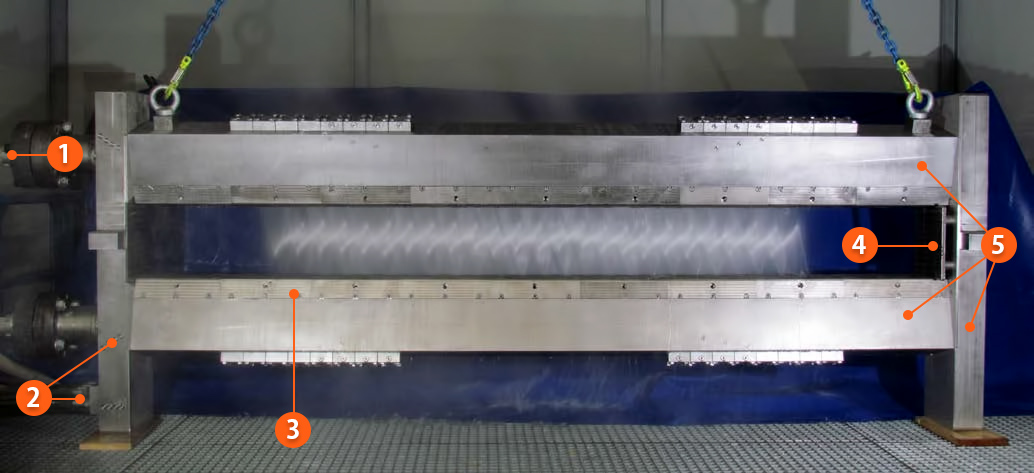

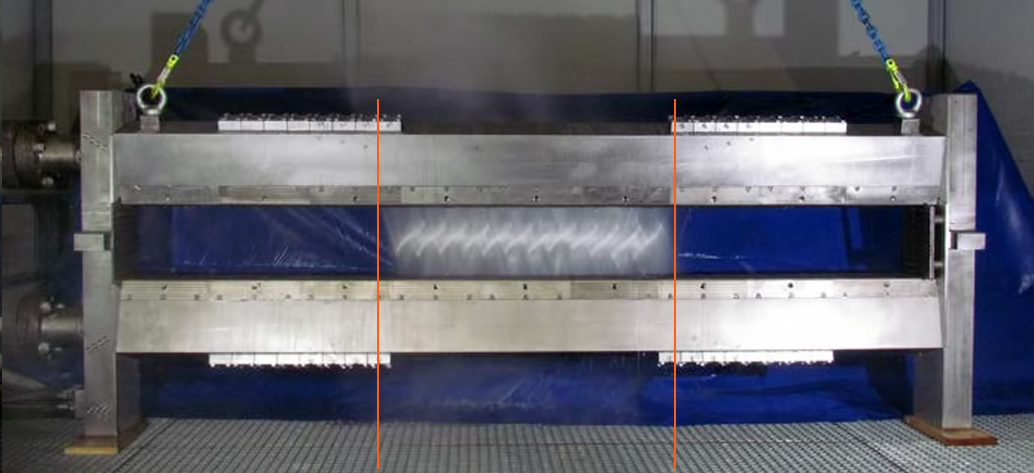

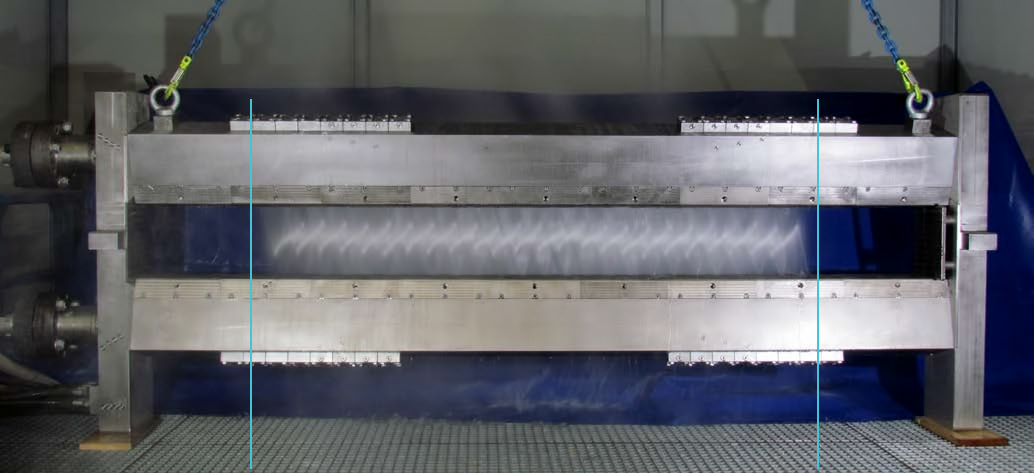

Selective Descaling HP²scaledown

Evertz Selective Descaling

- Adapt to evergy descaling width

- No impact loss

- Energy saving

- External control – no piping on the spray bar

Descaling System with switchable nozzles

- 1 Medium Supply (process water)

- 2 Supply controlwater. Internal control bores, no costly piping!

- 3 Segmental exchange of weareplates.

- 4 Racks and supports are protected by special liner plates.

- 5 Top / Bottom Spray Bar & rackall stainless steel.

Intermediate zone = min.

plate width (permanent spraying)

According to plate width the nozzles in the outer zones are switched additionally

Features

- Wear reduce : the nozzles can be switched according to plate width.

- Energy saving: at approx. 225 bar @ 87 l/min = approx. 45 kW per nozzle.

- Flexible: thedesign / installation space can be adjusted accoring to customers requirements.

- Safety: external control, nopiping/ electricityon thespray bar.

- Long-lasting: theHP²scale down - systems are successful in operation for several years.

- Basic Know How: Use of reliable HP²duraseal Technology.

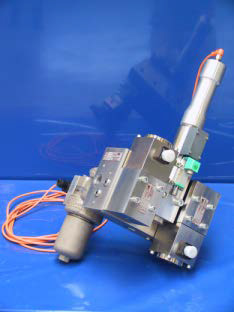

Valve Unit DN80 PN250 incl. Pressure Reducing Orifice

HP²scaledown Pump Protection Valves / Minimum Flow Valves

Valve Unit DN80 PN250 incl. Pressure Reducing Orifice

- Optimal designed to pump capacity curve

- Accuracy 5%!

- Energy saving

- High service life

Basic Valves & Accessories

Basic Valves

DN16–DN250 PN350 bar

Manual Shut-off Valves

DN16–DN250 PN350 bar

Valve Combinations

DN16–DN250 PN350 bar

Descaling Valves

DN16–DN250 PN350 bar

Motor operated Shut-off Valves

DN16–DN250 PN350 bar

Valves for Cooling Lines

Accumulator Shut-off Valves

DN16–DN250 PN350 bar

Valves for special Applications

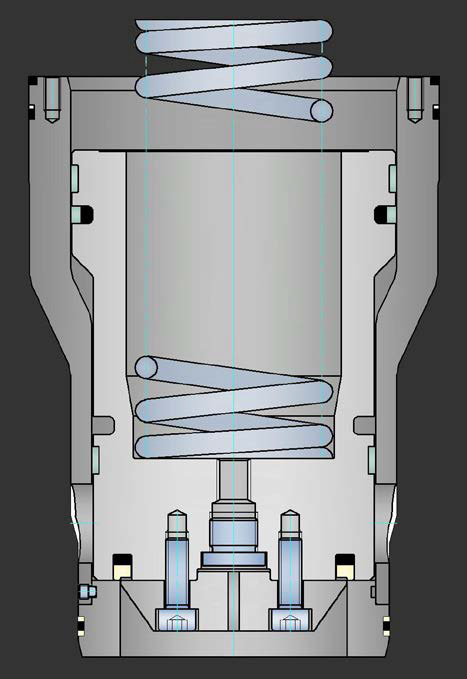

2/2 Way Cartridge Valves

Special Features:

| Nominal diameter | DN16 -DN250 |

|---|---|

| Max. operating pressure | 350 bar (800 bar) |

| Min. operating pressure | 5 bar |

| Media | Water, water-oil-emulsions, scale water, hydraulic oil, aggressive media, press. air |

| Max. operating temperature | 70°C |

| Min. operating temperature | 60°C |

| Recommended filtration | min. 100 μm |

| Installation space | according to DIN24342 (DN16 -DN100); internal standard DN125 -DN250 |

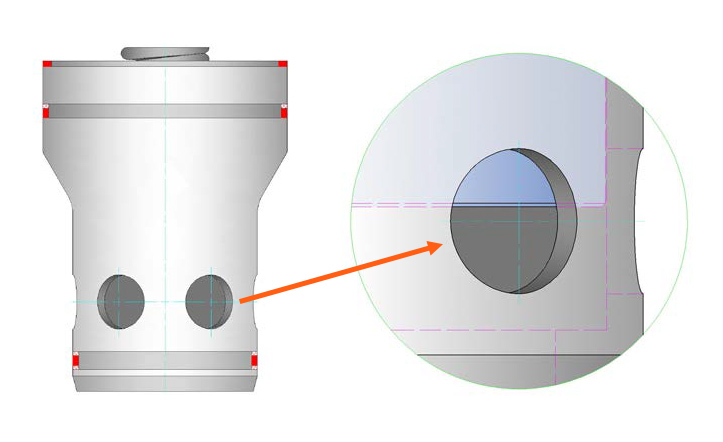

Cartrdge Technology

- Short downtimes in case of repairs due to the cartridge design.

- Use of most modern materials and sealing elements–long service life, minimum maintenance requirements.

- Valve piston arranged in flow direction, guided with guiding elements.

- Leakage-freeevenin case of heavy contamination due to special Evertz Soft-Seat Technology

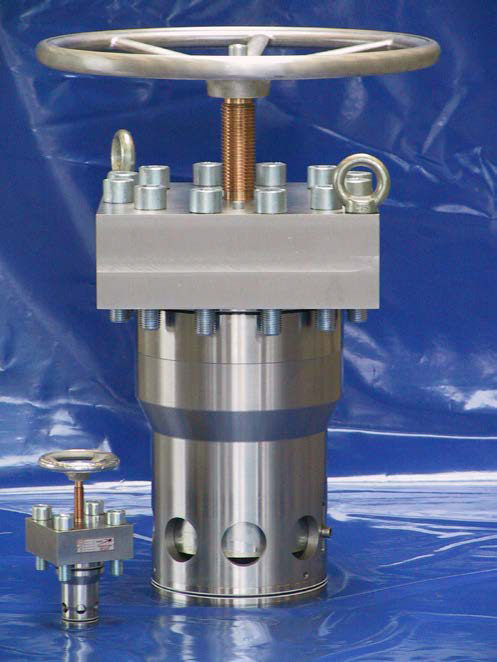

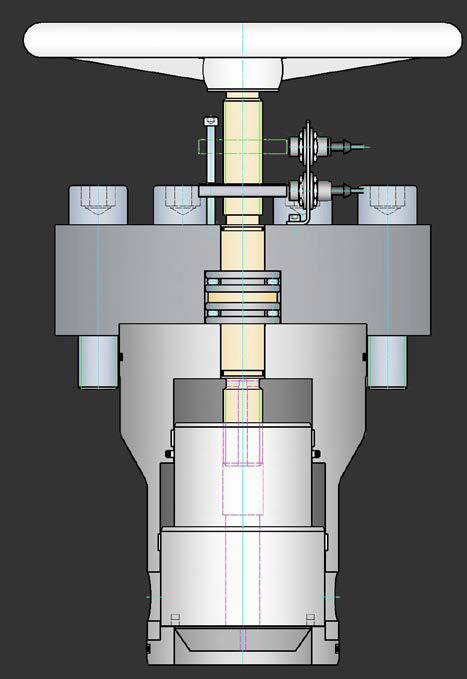

(Manual-) Shut-off Valves

Special Features:

| Nominal diameter | DN16 -DN250 |

|---|---|

| Max. operating pressure | 350 bar (800 bar) |

| Min. operating pressure | 5 bar |

| Media | Water, water-oil-emulsions, scale water, hydraulic oil, aggressive media, press. air |

| Max. operating temperature | 70°C |

| Min. operating temperature | 60°C |

| Recommended filtration | min. 100 μm |

| Installation space | according to DIN24342 (DN16 -DN100); internal standard DN125 -DN250 |

Cartrdge Technology

- Low actuating force even at full operating pressure

- No rising spindle

- Visual position indication (electrical indication optional)

- Ball bearing spindle

- Short downtimes in case of repairs due to the cartridge design

- Use of most modern materials and sealing elements–long service life, minimum maintenance requirements

- Valve piston arranged in flow direction, guided with guiding elements

- leakage-free even in case of heavy contamination due to special HP²duraseal

- Suited for changing flow directions

- Also available with rotary drive

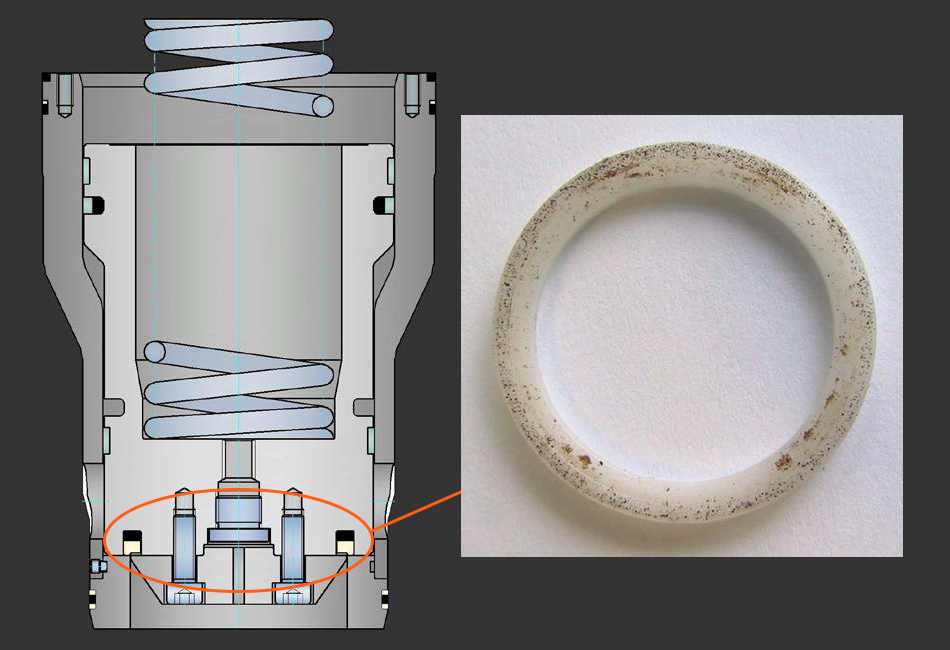

Evertz Hydrotechnik HP²duraseal

HP²duraseal

- Scale-/ Dirt particles are embedded in the HP²duraseal

- Never the less the seat tightens safe

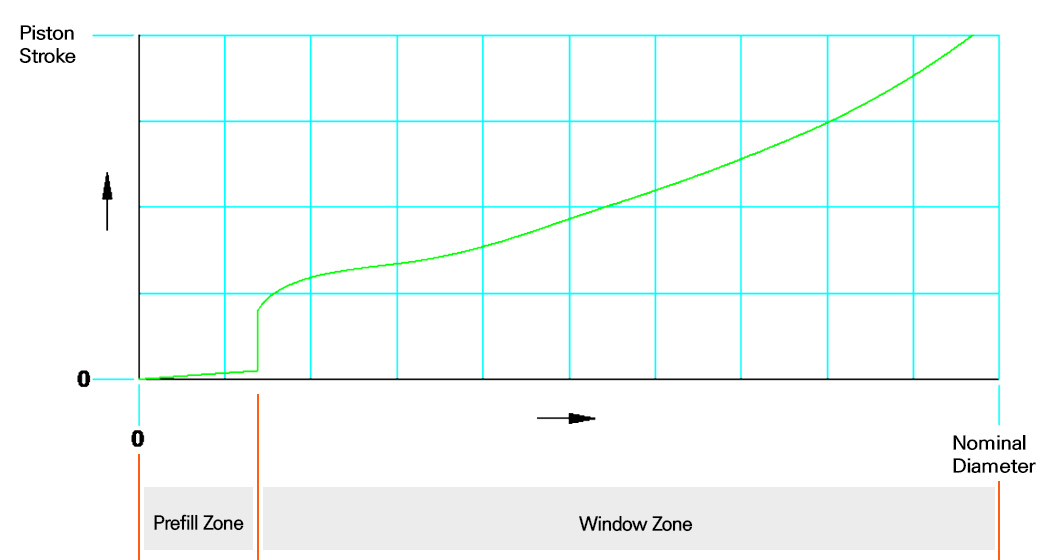

Prevents Water Hammer

Techology

- Smooth opening and closing due to special "Window Technology"

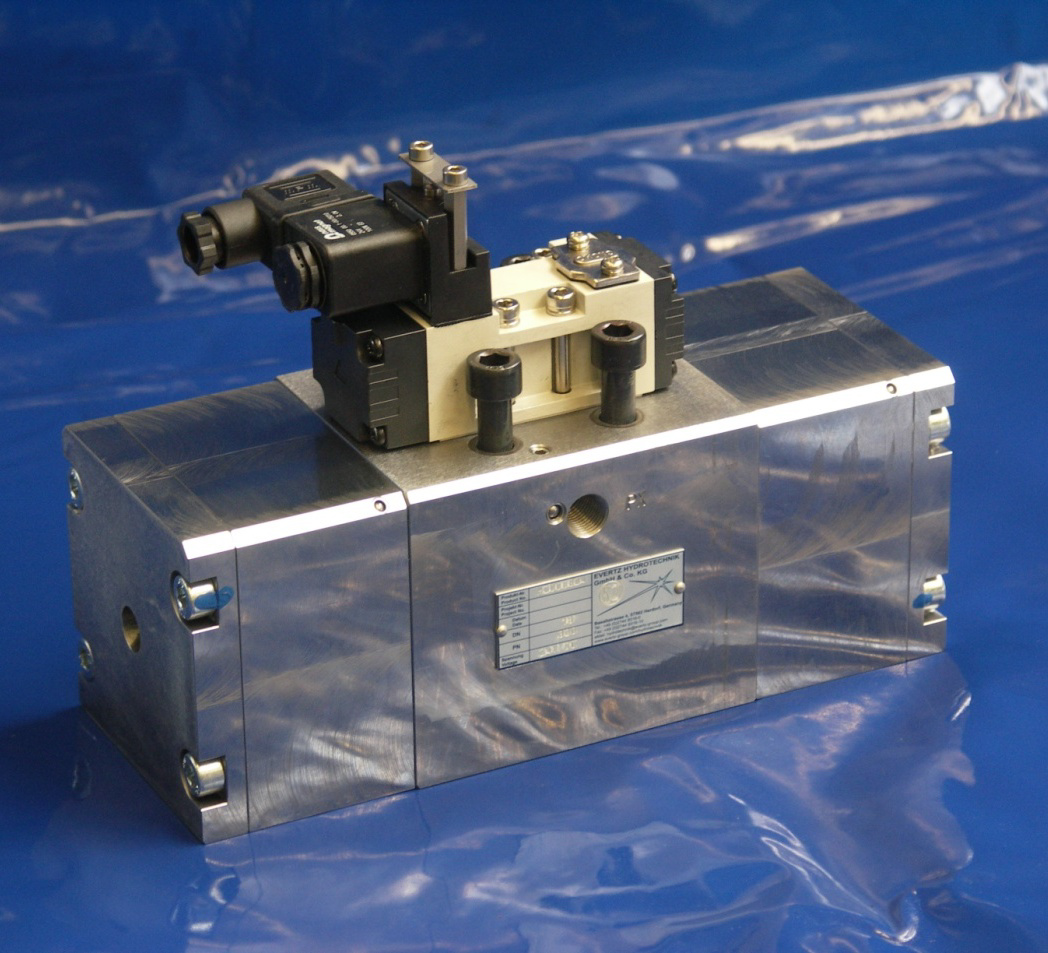

3/2 Way Valves HP

HP²duraseal Technology

- Nominal diameters DN10 –DN40

- No additional filtration necessary

- Maintenance free

- Extremely long service life

- Absolutely leakage-free

Technical Data:

| Nominal diameter | DN10 –DN40 |

|---|---|

| Operating pressure | Standard max.400 bar |

| Special series | Up to max.475 bar |

| Control | Pressurized air |

| Control pressure | 4-10 bar |

| Media | Water, HFA |

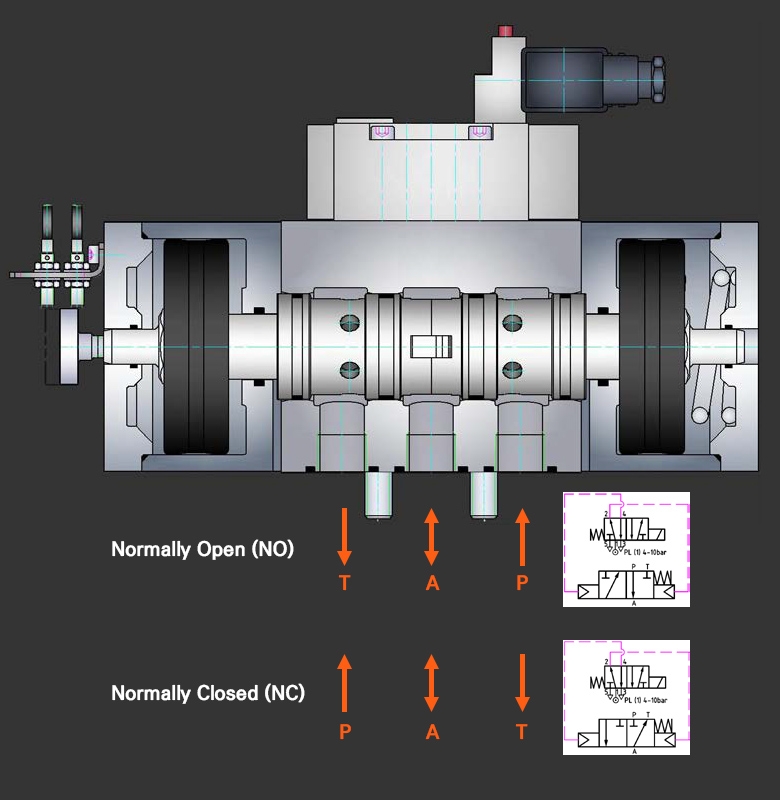

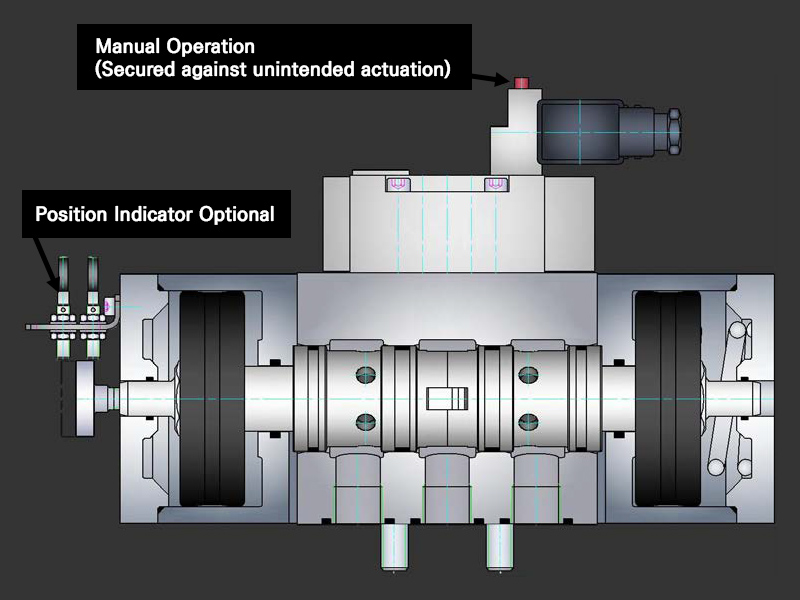

Special Features:

- Based on reliable Cartridge High

- Performance (HP) HP²duraseal technology

- Significantly longer lifetime in comparison to hard seat valves

- Highest reliability

- Almost maintenance-free

- Depending on main filtration no filter (or just worst-case filter) necessary

- NO- and NC type in one valve

- Optional optical / electrical position indicator possible

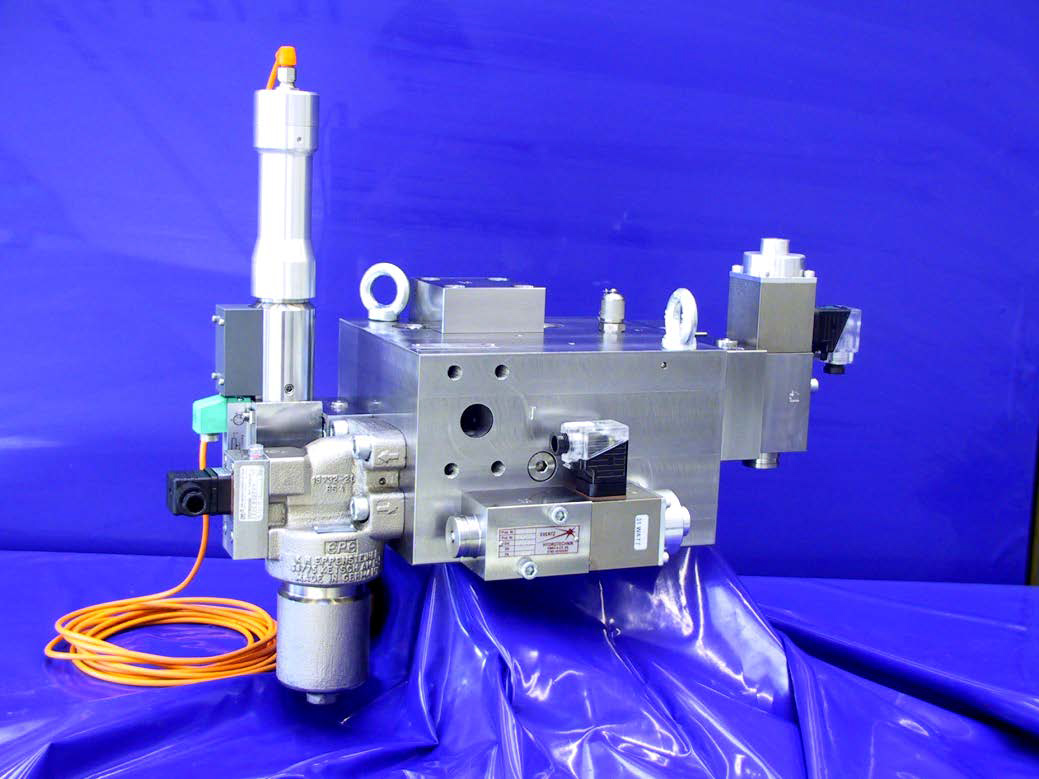

Valve Technology for special Applications

Valve Unit DN100/DN40 PN250

Valve Technology for Roll Balancing

Valve Unit DN63/DN25 PN250

Valve Technology for Roll Balancing

2/2 Way Valve DN32/DN50 PN8

Valve Technology for Roll Balancing

Valve Technology for Cooling Lines

3/3 Way Valve Unit DN50 PN25

Valve Technology for Pipe Cooling

Proportional Valve Technology