Development of Evertz grinding

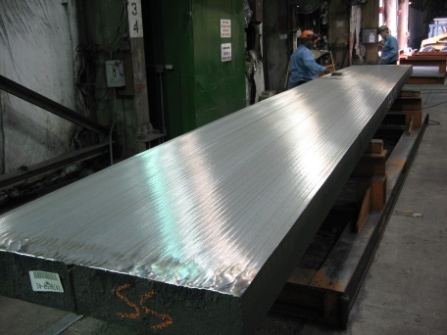

Before semi-finished steel-made material by rolling or forging can be treated with further processing, certain parts and defects might have to be sparked out. Sometimes a subsequent grinding of the complete surface of slabs and billets is necessary, too. Even in other areas of steel treatment, grinding is often preferred over other surface-treatment procedures.

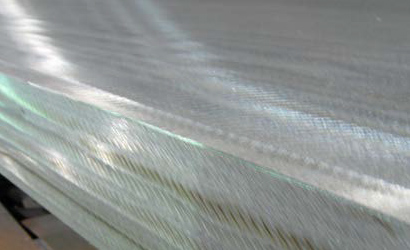

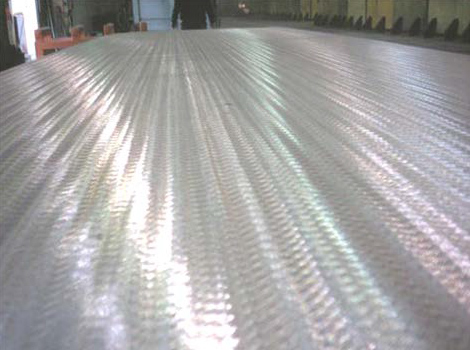

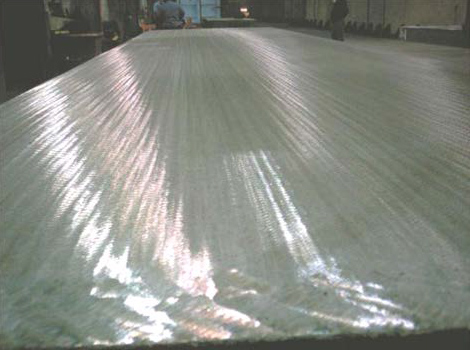

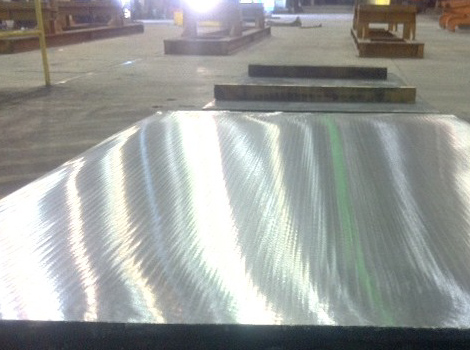

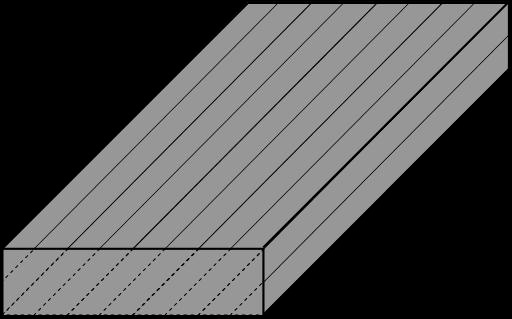

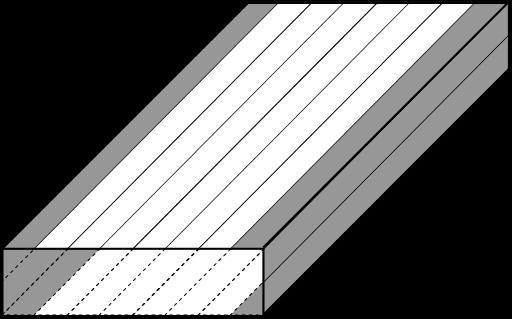

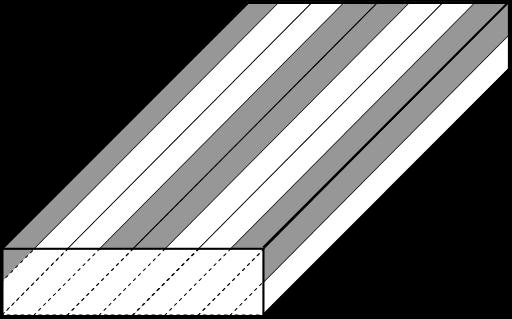

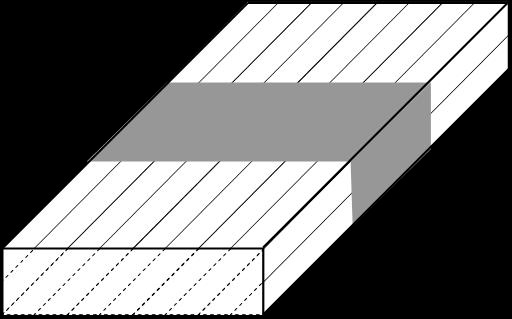

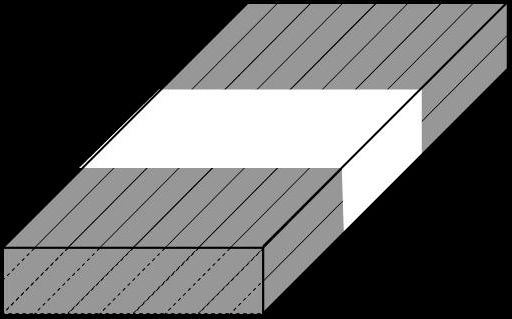

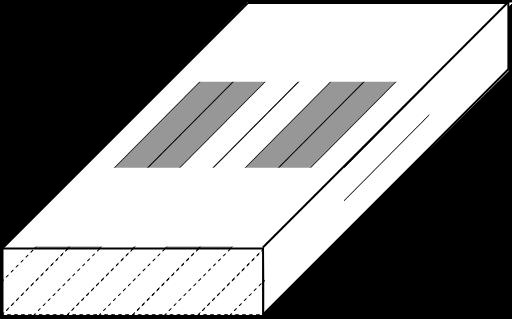

Our specialization includes the job grinding of slabs, blooms, billets, sheet bars, ingots, etc., achieving the correct quality of surface finish for specifications using axial, radial and cup grinding wheels. Depth of roughness ranging from 160µ to 30µ ispossible, as well as hot grinding, 45° grinding angle and special ground-surface patterns.

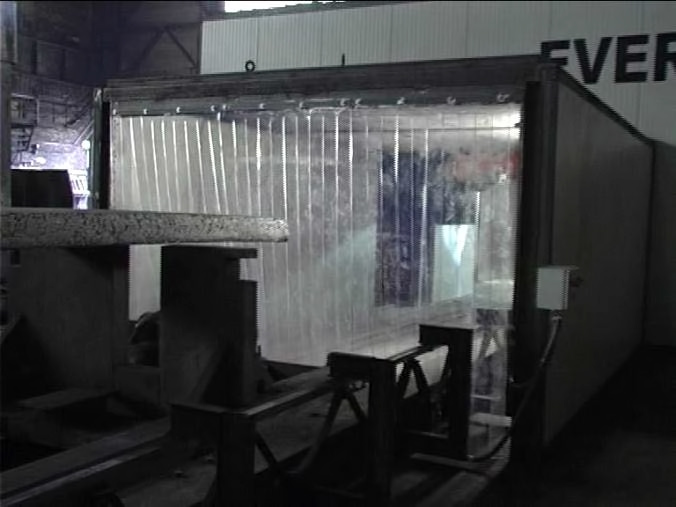

It's not a coincidence that we've been able to combine quality and affordability. Evertz integrates the know-how of a grinding-machine producer with the experience of a grinding service. We grind for you - anywhere and anytime!

High pressure Grinding

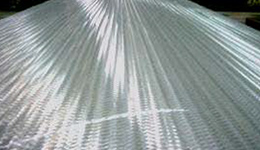

Before further processing of semi-finished steel products by rolling or forging, it is necessary to grind out defects in some places, but in some cases also to grind the entire surface. In other work on steel products, too, grinding is often given preference over other surface treatment methods.

Our competence: Contract grinding of slabs, blooms, billets, blanks, round material, ... the right surface quality for every surface.

Quality combined with low costs is no accident. EVERTZ combines the know-how of a machine tool manufacturer with the long experience of a grinding service provider.

We grind for you - anywhere, any place.

- All types of steel including carbon, stainless alloys and other metals such as nickel and titanium.

- Any steel product - geometries (slabs, blocks, billets, blooms, round products ...)

- At any angle (usually 45 ° or 90 °)

- Grinding specifications according to cutomer requirements and the degree of defects to be eliminated (test, point, partial or complete grinding)

- Surface quality according to customer requirements (usually from 135μ to 30μ)

- Hot grinding of steel products up to 800 ° C

- Selective grinding to minimize material loss

- Advantages compared to scarfing:

- no gas and oxygen consumption

- no Co2 emissions

- no water consumption

- no introduction of temperatures into temperature-sensitive steel grades

- significantly lower investment costs and thus lower fixed costs per t for the customer